Since the spread of the epidemic, the demand for medical drugs, disinfectant and other prevention and control materials has increased significantly. Faced with the severe situation, many disinfectant water manufacturing companies need to race against time to resume work. In the face of personnel shortages and limited supply of raw materials, disinfectant water manufacturers should do everything possible to expand production capacity and increase output, quickly putting disinfectants on the market, and providing material support to protect the health of families and individuals and defeat the epidemic.

In mass production, the use of automatic lines can improve labor productivity, stabilize and improve product quality, improve labor conditions, reduce production area, reduce production costs, shorten production cycles, ensure production balance, and have significant economic benefits. Due to its own characteristics, the Rongbai peristaltic pump filling system is used by more and more filling companies in their automated production lines.

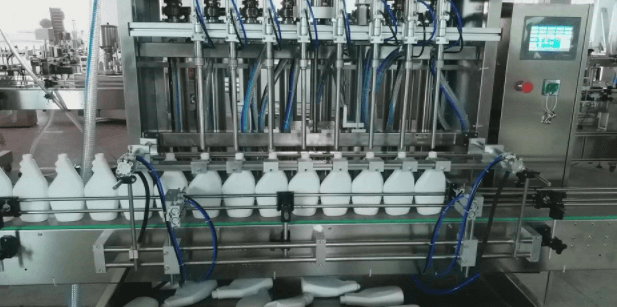

The peristaltic pump filling system FK600 independently developed by Rongbai is suitable for use on automated filling machinery. The system has multiple filling channels running synchronously. One controller can control up to 32 channels, which improves the filling efficiency. The filling accuracy of the system is high, and the accuracy is even higher after calibration. It is a small-volume, high-precision filling system. Provides reliable solutions for installation needs. The filling system can be operated online with the automated production line, and not only reduces human intervention in parts replacement and maintenance, but also reduces downtime, which will help improve the production line's production capacity and efficiency and meet the rapid growth of market demand.