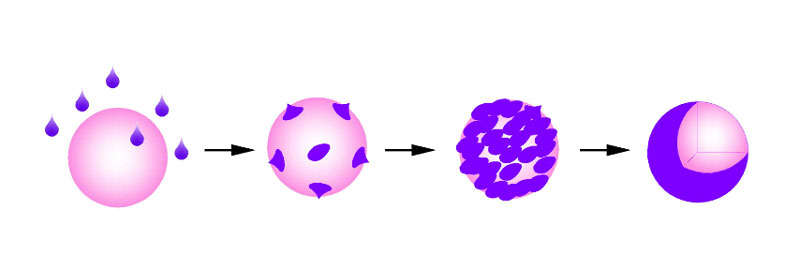

The coating process is to apply certain film-forming materials to the outer surface of the drug solid preparation in a specific equipment according to a specific process, so that it becomes one or several layers that adhere closely to the surface after drying. Multifunctional protective layers of different thicknesses and elasticities can achieve many purposes, such as improving drug stability, masking bad drug odors, reducing drug irritation, delaying and controlling drug release, preventing drug incompatibility, improving beautifying appearance, and making it easier to take.

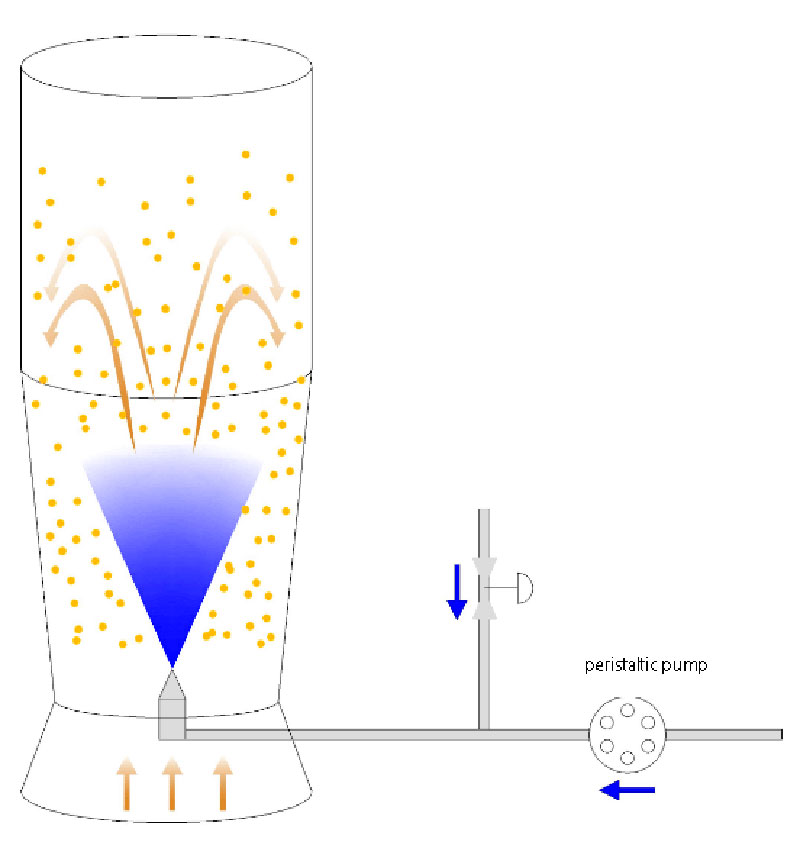

The equipment used for coating is called a coating machine, and there are many types, mainly including traditional water chestnut-type coating pots, high-efficiency film coating machines, fluidized bed coating barrels, etc. The working principles of various coating machines are basically the same. They spray the coating liquid onto the rotating material in an atomized manner, and use the heating system to make the coating liquid dry quickly after contacting the surface of the material and adhere to it. A film coating forms on the surface.