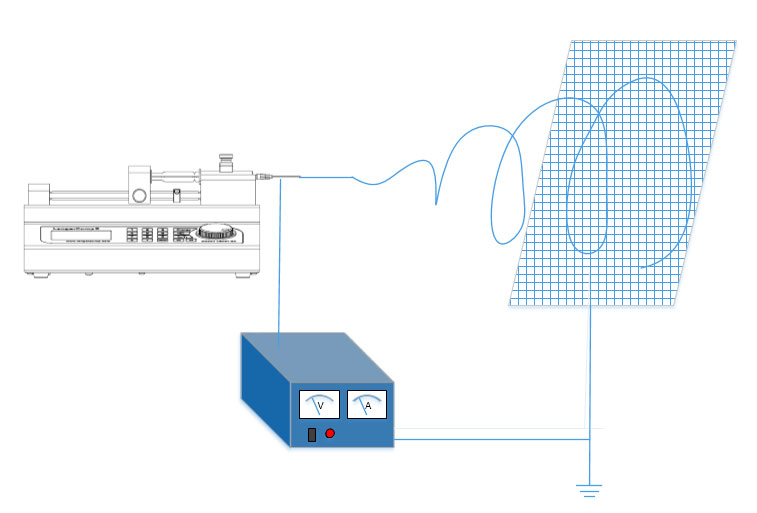

The electrospinning device mainly consists of a syringe pump, a syringe, a high-voltage power supply and a receiving device. Among them, the positive and negative poles of the high-voltage power supply are connected to the syringe needle and the receiving device respectively, and the receiving device is also diverse in form, which can be a stationary plane, a high-speed rotating roller, a disc, or a special-shaped bracket mold, etc. Spinning parameter settings, environmental conditions, etc. have a crucial impact on the spinning effect.

Factors affecting electrospinning

There are many factors and process parameters that affect electrospinning, which can be classified into 2 categories:

① System factors, including the molecular weight of the polymer, molecular weight distribution and solvent properties such as (viscosity, conductivity, dielectric constant and surface tension), etc.;

② Electrospinning process parameters, including applied electric field strength, solution concentration, solution flow rate, spinneret size, distance between spinneret and receiver and environmental conditions (temperature, humidity, air flow rate), etc.;

Among them, the choice of solvent, the stability of the injection speed, the concentration of the solution, the intensity of the applied electric field and the distance between the spinneret and the receiver are the main factors that affect spinning.

Recommended products: Electrospinning syringe pump