Different hoses are resistant to repeated squeezing by rollers and have different friction capabilities.Different pipe types, pipes, pump heads, and operating speeds have different lifetimes.The service life is called flexible life in the pump system. In specific applications, the characteristics of the pump are very consistent.Choose a long-life, thick-walled pipe and a large-flow pump, which can obtain a longer hose service life when running at a lower speed.

Under pressure:

The application of peristaltic pumps is limited by the pressure-bearing performance of the hose.

If the system pressure reaches more than the limit pressure of the hose, the hose will expand, resulting in excessive wear of the hose or hose rupture.

The factors that affect the pressure of the hose are: material, the ratio of diameter to wall thickness, etc.

temperature:

The adaptation of the hose to the operating temperature range is a factor for users to consider.Different materials have different temperature manifestations.

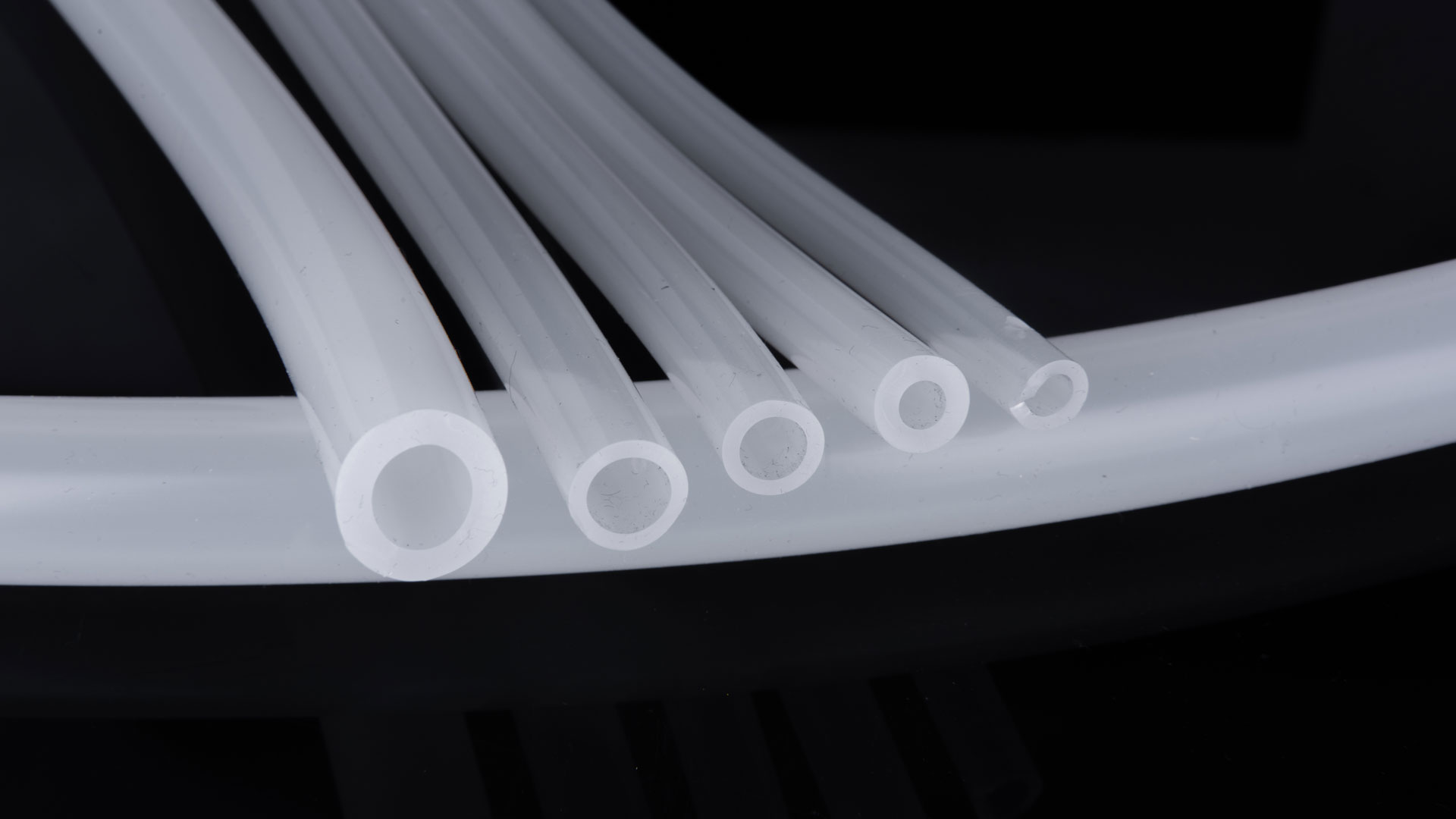

size:

The size of the hose has a direct impact on the flow rate. An excellent pump design will consider the inner diameter and wall thickness of the applicable hose to match the best hose size or pipe number range.soft

The inner diameter of the tube determines the flow rate; the wall thickness affects the ability of the hose to be compressed and rebound, and it also has a great impact on the life of the hose.

certification:

Hoses may have to pass relevant certifications when they are used for related purposes.Such as the US Pharmacopoeia standard USP, the European Pharmacopoeia standard EP, and the US Food and Drug Administration standard

FDA, USDA standard USDA and National Health Foundation standard NSF.